A Beijing-based energy company has taken a major step toward commercial airborne wind power after completing the maiden flight and grid-connected power generation test of its megawatt-class system in Southwest China.

The test took place on Sunday in Yibin, Sichuan Province, where the floating wind power platform rose to about 6,560 feet (2,000 meters) and successfully delivered electricity to the grid, as reported by China’s state-backed Global Times.

During the trial, the system climbed steadily to an altitude of about 6,560 feet and generated 385 kilowatt-hours of electricity that was fed directly into the local grid. The test marked the first real-world demonstration of power generation for the S2000 floating airborne wind energy system, also known as SAWES.

The developer, Beijing Linyi Yunchuan Energy Technology, described the S2000 as the world’s first megawatt-level airborne wind power system designed for use near urban areas.

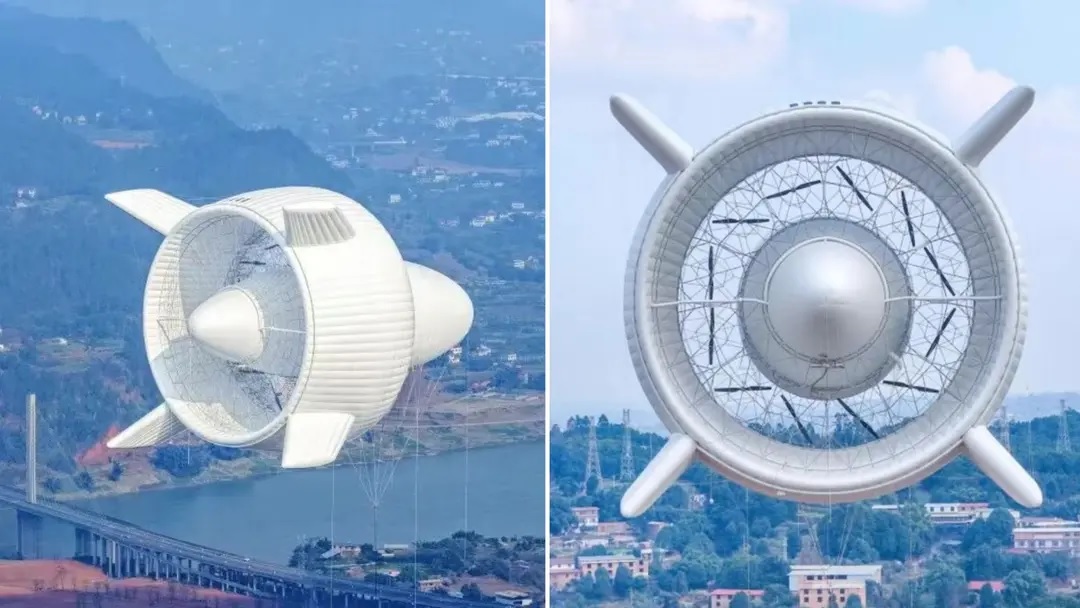

Visually, the platform resembles a fantasy-style airship, featuring a large, floating envelope and an integrated power-generating structure. The system measures about 197 feet long, 131 feet wide, and 131 feet high.

According to the Global Times, the platform took around 30 minutes to ascend during the Yibin test. After reaching its target altitude, it maintained a stable hover while operating its power generation equipment, a key milestone for future commercial deployment.

The world’s first MW-class S2000 Stratosphere Airborne Wind Energy System (SAWES) for urban use has successfully completed a test flight in Yibin, southwest China’s Sichuan Province. During the test, the system ascended to an altitude of 2,000 meters, generating and feeding 385… pic.twitter.com/CFynQ6h0b8— People’s Daily, China (@PDChina) January 13, 2026

According to Weng Hanke, chief technology officer of Linyi Yunchuan, the S2000 system relies on a helium-filled aerostat to lift a lightweight wind power unit into higher layers of the atmosphere. At these altitudes, winds tend to be stronger and more consistent than those near the ground.

Once airborne, the system converts wind energy into electricity and sends the power back to the ground through a tethered cable. This same tether also helps control the platform’s position and stability during operation. The approach allows the system to access wind resources that are largely out of reach for conventional wind turbines.

Weng explained that the company is targeting two main use cases. “One is for off-grid settings like border outposts, where it can serve as a relatively stable conventional energy source. The other is to complement traditional ground-based wind power systems, creating a three-dimensional approach to energy supply,” he said, as reported by Tide News.

Research cited by Tide News notes that wind energy increases with the cube of wind speed. This means even modest increases in wind speed at higher altitudes can lead to several times more power generation compared to ground-based turbines, while remaining low-carbon and environmentally friendly.

To maximize this advantage, the S2000 uses a ducted design to concentrate airflow. The duct is formed by the space between the main envelope and an annular wing. Its role is to guide and compress the wind before it reaches the turbines, improving overall energy capture.

“It’s like wrapping the wind from all sides, constraining the airflow within this duct so that as much wind as possible is captured by the blades. We have deployed 12 wind turbines on this duct,” Weng told Hunan TV.

Thanks to this aerodynamic layout and a total volume of nearly 20,000 cubic meters, the system has a maximum rated power of up to 3 megawatts, according to company data.

The company has already started small-batch production of the S2000 and has signed letters of intent with several coastal cities and high-altitude regions interested in deploying the technology. To support larger-scale manufacturing, Linyi Yunchuan is building a production base for high-performance envelope materials in Zhoushan, Zhejiang Province.

The facility is expected to reach an annual output of 200,000 linear meters by 2026 and expand to 800,000 linear meters by 2028. The goal is to reduce China’s dependence on imported materials used in high-altitude wind systems.

The project represents a meaningful breakthrough for future clean energy development. However, he cautioned that the technology is still at an early stage, with long-term stability, safety, and cost performance yet to be fully proven.